So you have, or want to introduce, a containerized shelf-stable product to the consumer-packaged goods (CPG) market. Batch retort solutions offer the greatest range of technology and flexibility versus any other type of commercial sterilization process solution.

Here are some key considerations to guide you through choosing the appropriate batch retort process for your commercial sterilization needs.

What type of retort do I need?

The type of batch retort needed for commercial sterilization is determined by two main factors – product and container.

Product Characteristics

Product characteristics will decide if a method of agitation will be beneficial or required during commercial sterilization. For instance, products that contain a dairy ingredient will typically require agitation to prevent “burn-on.” This is the undesirable result of one or both of two reactions.

- The first is known as the Maillard reaction. This chemical process sees certain sugars and amino acids reacting under high heat to form a new chemical compound.

- The second reaction is caramelization, which is the pyrolysis of certain sugars.

- The high heat of commercial sterilization (±250°F / 121°C) can also affect other ingredients in an undesirable manner.

Agitation, also referred to as forced convection, is essentially stirring the product in the container. This reduces the time that a product needs to be subjected to high heat.

Agitation offers two significant benefits:

- Better product quality

- Higher throughput due to faster rates of heating and cooling

Conversely, some products are better with a static process and long cook times to optimize product quality. These products undergo a different type of heating known as conductive heating (and cooling). Examples of products that do not need agitation include:

- Baked beans and similar products in heavy sauce

- Loaves and pâtés

- Other high viscosity foods

- Products that are filled into the container with no head space

Types of Containers

Container type also plays a role in determining what agitation type is most appropriate to protect or enhance the quality of the product inside. Characteristics of containers being used determine the type of process or processes the retort will need to perform.

Rigid containers, like steel cans, are structurally strong and can be processed with a saturated steam process without overpressure.

Overpressure–also referred to as counterpressure–is the added pressure above the saturated steam table pressure (i.e.: 15 psig / 1 bar = 250°F / 121°C) that is needed to appropriately protect the integrity of the container and its hermetic seal during the retort process. Overpressure retort processes include steam-air, water cascade, water spray, and water immersion.

Other rigid containers, like glass jars and bottles, do require an overpressure water immersion process. Without overpressure, the closure or lid may not maintain a hermetic seal as pressure builds inside the container during the heating process.

For shelf-stable ready-to-drink (RTD) beverages. the glass containers are often agitated via end-over-end rotation. The buoyancy created by the water inside the retort (known as the Archimedes’ Principle) protects the fragile glass containers by reducing the clamping force needed to secure the load. This lowers the stress on the lid that could damage the hermetic seal.

Semi- or non-rigid (i.e.: flexible) containers, such as pouches and other polymeric containers (plastic bowls, cups, trays, and bottles) also require an overpressure process. This prevents expansion of the container during heating, which can impact the integrity of the container. When its integrity is compromised, the container can deform or damage the delicate seals and seams, registering the product unusable.

What size retort do I need?

Mandate Time

Mandate time is the elapsed time allowed from when a container is hermetically sealed to when the retort process must commence. Mandate time is important for two primary reasons:

- First, to prevent food spoilage before retort processing begins. Certain products (like wet pet foods) have high bacterial loads and can spoil extremely quickly after the container is sealed.

- Mandate time also addresses another critical process factor: initial product temperature (IT). Product IT is a parameter within the process filing, which is submitted to the FDA or USDA per federal regulations. Surpassing the mandate time may allow the product to cool below the IT, thus causing a process deviation.

It is best to calculate the retort capacity so that it can be completely loaded and the process started within the required mandate time. If not, partially loading the retort will be necessary, which is not very efficient.

Manual vs. Automation

Manual versus fully automated batch retort systems also plays a role in determining the size of your commercial sterilization retort. For example, if baskets or trays of containers are manually delivered to and from the retorts, it is advisable to go with smaller diameter retorts. This is to ensure the loads are more manageable and safe to move around by operators. This may require more retorts to meet the operational speeds that are expected.

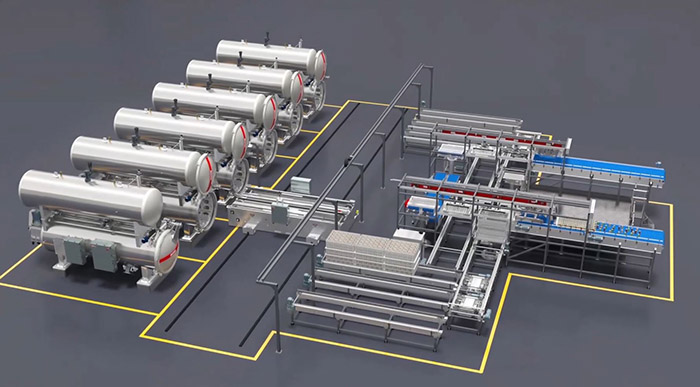

Automated batch retort systems (ABRS) can handle much heavier loads because all material handling is mechanized. Large diameter retorts can be used in these applications for larger scale commercial sterilization.

How many retorts do I need?

Determining how many retorts are required in a batch retort system is based on several factors as well, including:

- The above size-determining factors of mandate time and the level of automation

- The desired throughput or line speed is most commonly stated in containers per minute. In order to avoid the retort(s) being a throughput bottleneck, sufficient retort capacity is needed.

- Finally, overall process duration. Batch retorts operate a series of steps during a process, including:

- Come-up to temperature

- Cook/hold

- Pressure and atmospheric cooling

- Unloading

Typically, you want to maximize the size (i.e.: capacity = diameter x length) of the retorts to minimize the number of retorts needed. This reduces the upfront expense for retorts and ancillaries, installation costs, future maintenance costs, and floor space requirements.

If you have any questions about determining your batch retort equipment needs for commercial sterilization, please visit www.Allpax.com, email info@allpax.com, or call us directly (985) 893-9277.