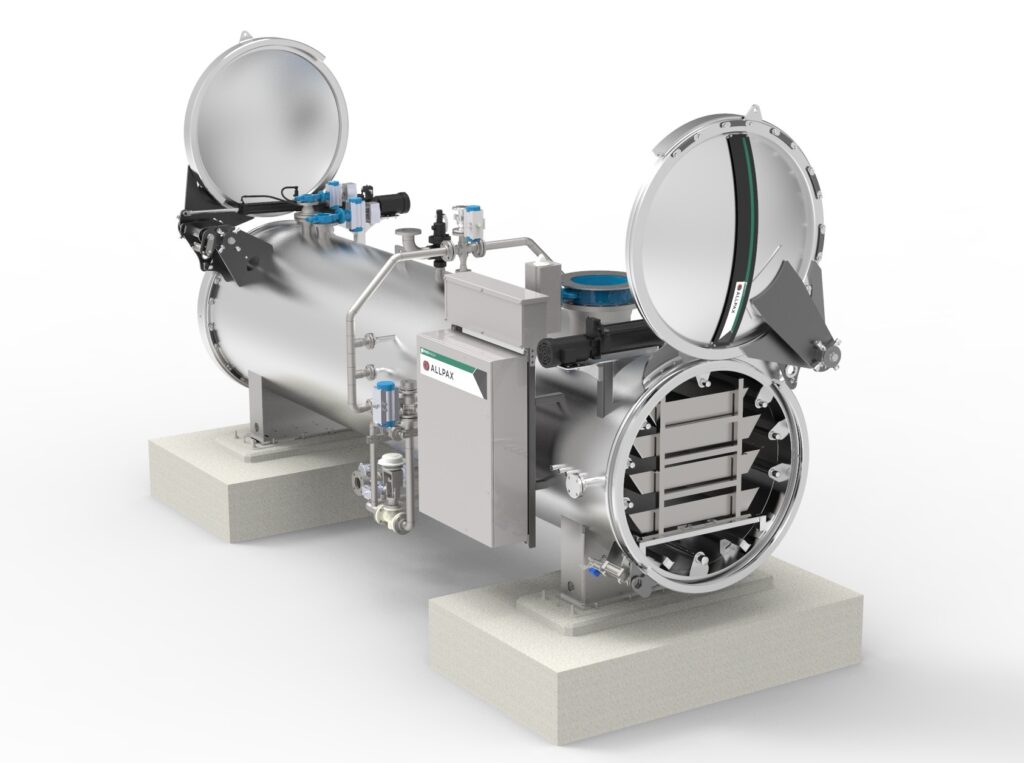

A retort that cooks product and also brings the product down to refrigerated temperatures without mechanical refrigeration

When large volumes of a food ingredient are processed in a prepared foods manufacturing line, it is almost always desirable to bring the product up to cooking temperature and back down to the desired mixing or blending temperature as soon as possible. Some examples of such ingredients are potatoes, green beans, chickpeas, and even seafoods. The vacuum-cooled product cooker (VCPC) is a specialized retort that achieves these tasks in high volume food production applications. The purpose of this white paper is to describe the cooking and cooling processes performed by the VCPC, the specialized features of this piece of thermal processing equipment and to highlight some benefits it brings to an industrial food preparation operation.

The Thermal Process

Following is a description of the physical properties of the environment in the VCPC in its various phases or steps of operation.

Pre-Vacuum Step

After product loading and prior to the cooking step a vacuum is pulled on the sealed vessel. This is done to remove as much air as possible. Because air is an insulator in a steam environment removing it prevents cold spots in the vessel and allows for even temperature distribution in the process environment.

Come-Up-To-Temperature Step

After the desired level of vacuum is reached, steam is injected until the desired cook temperature and pressure setpoints are met.

Cooking Step

The cooking of the product is done with saturated steam at elevated temperatures (i.e.: typically above 212ºF). This is made possible because the VCPC is an ASME (U.S.) pressure rated vessel. As with a stovetop pressure cooker the elevated temperature allows for shorter cooking cycles.

Vent Step

The vent step is simply what the name implies. A valve is opened to release the pressurized steam from the vessel. Once the internal vessel pressure reaches ambient (atmospheric) pressure the cooling step begins.

Cooling Step

A unique feature of the VCPC is the method by which the product is brought down to refrigerated temperature. This method of cooling is known as evaporative cooling and is achieved by pulling a vacuum in the vessel. There are two options for vacuum generation, steam ejectors or mechanical vacuum pumps. A steam ejector uses the venturi effect to generate vacuum with pressurized motive fluid (steam) and condensers (heat exchangers). Depending on the desired vacuum and volume of the VCPC, multiple stages of ejectors and condensers may be required. The mechanical vacuum pump is usually a liquid ring vacuum pump. The degree to which either of the two options reduces the pressure in the vessel determines the temperature to which the product is lowered to and the size of each determines the speed in which it is done. Additionally, these two methods may be used in conjunction.

The same relation of pressure to temperature and how it applies to the saturated steam principle, also applies in a vacuum environment. Thus, conversely to the cooking step, the lower the pressure is reduced to in the retort environment, the lower the temperature that can be achieved. In addition to the vacuum environment during the cooling step, a fine mist of water is introduced to the cooked product to aid in the evaporative cooling and to prevent the desiccation of the product.

Benefits of Using a VCPC

Product Quality

Because the (VCPC) also performs the cooling, the product does not need to be transferred from the cooking vessel to either another receptacle like a bulk product bin or a conveyor. This amounts to the elimination of an entire product transfer step. The immediate transition from cook to cool also reduces the potential of over cooking. Cooking with saturated steam reduces the leeching of desirable ingredients compared to boiling. Because a product is usually more delicate when cooked than raw, the reduction of ingredient handling lessens the potential of product damage and reduces yield loss. Also, because there is less handling of the product, there is a reduction in the possibility of the product being contaminated with food-borne pathogens such as listeria, cholera, salmonella and E. coli.

Production Line Speed and Efficiency

As stated earlier, a pressurized environment allows for cooking at elevated temperatures compared to atmospheric cooking (steaming or boiling) allowing for shorter periods. The same steam saturation principle applies to vacuum (evaporative) cooling. Reducing the cooking and cooling (thermocycle) time increases throughput for a production line and reduces the material handling equipment required. This applies to both mechanized (fewer conveyors, augers etc.) as well as less bulk containerizing. It also reduces the amount of clean in place (CIP) and manual/mechanical cleaning equipment and personnel required. VCPC’s also reduce the amount of refrigerated real estate required in an operation. Lastly, the use of a VCPC allows for a fully automated thermal process from the loading of raw product to blending and/or mixing operation. An example of such a process involves taking room temperature diced potatoes, cooking them to desired consistency and cooling them back down the desired temperature for blending/mixing in about 35 minutes without ever touching or moving the ingredient.

Environmental Implications

Because the process of cooling in a VCPC is refrigeration free, the amount of chemical refrigerants such as ammonia, freon and inert gasses such as carbon dioxide and nitrogen are reduced. With the ongoing pressure to reduce our footprint on the environment, the Vacuum Cooled Product Cooker is the solution for a “green” food manufacturing operation.