By Jeff Arthur, Technical Sales Director, Allpax, a ProMach product brand

Because stainless steel is easily cleaned and does not rust under normal conditions, it is the preferred metal for food processing machines used in wet environments. A little-known fact about stainless steel is that it is prone to unique types of corrosion when the metal is exposed to a specific set of environmental factors. These corrosion producing conditions can exist during the operation of stainless-steel batch retorts and are not easily realized or recognized. Unless steps are taken to identify, reduce, or eliminate the causes of corrosion, batch retorts may have their service lives cut short, resulting in production disruptions and the need for early replacement of affected vessels.

Modern retorts and their internal wetted parts are commonly made from 300-series stainless steel. Understanding the root causes of corrosion in stainless-steel retorts can be complex; however, there is a common theme in how most of the problems start. The standard retort has an internal environment of high temperature and pressure created by steam, water, and oxygen, all of which are normal operating conditions for a retort. When excessive harmful chloride ions are present inside, or even on the outside of the retort, regardless of how they were introduced the ions act as a catalyst for starting and accelerating corrosion in stainless steel during the retort cycle.

The terms chloride ions or chlorides are not to be confused with or solely blamed on the use of chlorine as a sanitizer. Chlorides are ions comprised of the element chlorine with a negative charge and can also be associated with salts. While chlorine sanitizers do add chlorides to the retort water, chlorides can come from many sources ranging from the incoming municipal retort water supply, a recycled water storage tank, product on the outside of containers, residual salt brine from an improper water softener regeneration system, or even chlorides from insulation materials, to name a few. Basically, when stainless steel is exposed to high temperatures, high stresses, and excessive amounts of chlorides, a corrosion reaction from the chlorides can start.

There are three different types of corrosion normally found in stainless-steel retorts: stress corrosion cracking (SCC), crevice corrosion, and pitting.

Stress Corrosion Cracking (SCC)

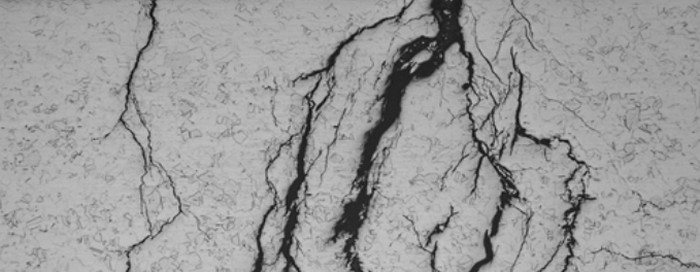

The most insidious is stress corrosion cracking (SCC), sometimes called chloride stress corrosion cracking. Once stainless steel begins cracking, the damage is permanent and not repairable. Highly stressed areas of steel inside the retort system are normally affected first. When high levels of chlorides, adequate oxygen, water, and high temperatures combine, the SCC corrosion reaction can start.

SCC infections weaken stainless steel, causing it to become brittle. The fact that metal is continuously expanding and contracting through repetitive heating and cooling cycles accelerates SCC when the corrosive conditions exist. There is no remediation for SCC affected metal once it has started. Removing a weakened section and welding in a new one is often ineffective as it just adds more heat and stress to the already affected area. The retort becomes unrepairable when the problem is in advanced stages.

Crevice Corrosion

The second type of corrosion found in stainless steel retorts, crevice corrosion, is caused by concentrations of chlorides filling small spaces between two parts or voids where water has stagnated. Only one part needs to be stainless steel, the other can be stainless or another material such as a gasket. As the retort cycle temperature and pressure increases, water combined with a concentration of chlorides works its way into small cracks lacking the free flow of oxygen over the area and the corrosion reaction starts. These crevices can be as small as .005 inch (0.127mm) when they start and grow to large pockets that are inches in size, eroding the metal away. As the retort fills and empties cycle after cycle, the concentration of chlorides in the cracks rises and becomes even more corrosive, enlarging or undermining the crevice and weakening the metal.

Pitting

The third type of stainless-steel corrosion commonly found in stainless retorts is pitting. When pitting corrosion has progressed, it is visible to the naked eye and sometimes is in open areas that are easier to see – but not always. Pitting does not always follow a set of rules on why one area is pitted, and one area is not, on the same steel surface. Small pits in the steel start to develop when the metal surface is exposed to ample amounts of chlorides, hypochlorite (chlorine), or bromide ions in the environment and no metal surface protection is present. Pitting in advanced stages can aggressively erode thick steel, causing leaks.

All three of the corrosion reactions mentioned above have chlorides as a common denominator in starting and continuing the corrosion within the retort and retort utility piping system.

How Do Chlorides Continue to be in the Retort and Go Unnoticed?

Chlorides in the retort cannot be seen by the naked eye, only the by-products of corrosion and then only by trained personnel. Water and steam chemistry tests can detect the level of chlorides in the retort water. Part of the problem is realizing there is one. In many cases where a corrosion monitoring program is not in place, the corrosion problem is not found until much damage is already done, causing production or maintenance issues. Understanding the root causes of corrosion in stainless-steel retorts requires an in-depth knowledge of the equipment, the water chemistry, how the production line operates, including compliance with federal regulations, and an understanding of the corrosion mechanisms. This set of skills can be spread across many departments within a food manufacturing plant and is not always located in one central place or area of responsibility.

Recommendations for Addressing Stainless Steel Corrosion

For plant operations to have a sustainable long-term retort system that meets the Code of Federal Regulations with the lowest possible corrosion rates, there needs to be an effective water treatment system, including chloride and PH control of the water, along with training of operations personnel and preventive maintenance monitoring.

The first step in remediation is an audit of the filling operation to understand the products being retorted and how the packages are conveyed into the retort. Testing the chemistry of the incoming steam and retort water should also be undertaken. And an interior inspection of the retorts, piping, and the retort utility support system should be performed by a team of auditors, under the direction of certified retort specialists, and should include water treatment experts and chemical suppliers. The auditors should make recommendations on:

- Filling operations and maintenance training as they relate to retort corrosion

- Treatment of the incoming steam and retort water based on chemistry analysis

- The type and setup of water treatment and corrosion control monitoring and chemical application systems, including passive monitoring utilizing metal corrosion coupons and/or active electronic monitoring

- Potential repairs and/or modifications to retorts and the utility support system based on current level and/or rates of corrosion

After corrective actions are in place, followup inspections, either from the auditing group or internally trained maintenance/plant engineering personnel, should occur on a quarterly basis to ensure correct procedures and practices are followed, and that results are within expectations. Routine audits, water treatment analysis, retort evaluation, and training are investments needed to keep retort room workers safe from corrosion-initiated hazards, to produce products of the highest quality possible, and to maintain production at high efficiency levels throughout the projected life of the retorts.

For information on the issues of corrosion in stainless steel and the Allpax 40-point inspection initiative, call 888-893-9277, or visit Allpax at www.Allpax.com.

About the Author: Jeff Arthur, Technical Sales Director, Allpax, has over 31 years of experience in the industrial food processing equipment industry, primarily associated with the design, manufacturing and sales/customer support of in-container, thermal sterilization/processing equipment