The Water Spray process is also an overpressure process, like water immersion, except that the product is exposed to the influence of the overpressure air. It is similar to the Saturated Steam process in that steam is the driving force for reaching the center of the load. But, the Water Spray process is different from Saturated Steam in that air can be introduced into the vessel during sterilization. Overpressure is provided by introducing air (or steam) into the retort. To overcome the insulating effects of the air, the spray nozzles vaporize the steam and mix the steam with the air.

Note on Terminology

In the Allpax retort control system there is terminology for an Uncleared Deviation or a (Cleared) Deviation condition that may exist. These terms are referred to in this paper. The definitions of these terms are as follows:

- CLEARED DEVIATION – When a deviation occurs, it may be possible to correct the process by adding time and/or temperature in order to compensate for the deviation. If this correction can take place in the retort, then the batch is declared to have a Cleared Deviation status. The Cleared Deviation status notifies the retort operator that a deviation was detected, but that corrective action was taken to compensate for the deviation (see Scheduled Process / Alternate Process definition). As in all cases, release of the product is subject to final review by the plant’s Quality Manager or Process Authority.

- UNCLEARED DEVIATION – When a deviation occurs in which an unsafe product condition exists and cannot be corrected for, then the batch is declared to have an Uncleared Deviation status. The Uncleared Deviation status notifies the retort operator that a deviation was detected and continues to exist in the batch.

Process Steps

Batch retorts execute a series of programmed process steps (also known as segments). These steps must be properly executed to achieve a sterilization process that meets the regulatory requirements imposed for food safety.

In a Water Spray process these steps are:

- Prepare Tank (OPTIONAL – if an external preheat water tank is used)

- Come Up Fill (A Sterilization Step)

- Come Up (A Sterilization Step)

- Cook (A Sterilization Step)

- Pressure Cool

- Atmospheric Cool

- Drain

The following is a detailed description of each step:

PREPARE TANK – WATER SPRAY

This is an OPTIONAL step that exists only if there is a preheat tank provided on the retort (Some retorts come equipped with a small preheat tank for preheating the process water while the operator is entering the process recipe information.)

The purpose of the Prepare Tank step is to heat (superheat) the water in the Storage Vessel – the hot water reservoir. The Temperature, pressure and level are all brought to recipe-defined set points to complete the step. It should be noted that the door must be detected as closed and locked, along with the door safety detected as engaged before the step can be exited to the first come-up step.

In addition, to the water level, pressure and temperature checks performed in the storage vessel, and the door safety check performed on the Process Vessel, an I.T. check is also performed. This process step will not be exited until the water temperature in the storage vessel is greater than the product initial temperature entered by the operator.

COME UP / FILL – WATER SPRAY

The purpose of this step is to fill the bottom of the retort with water (to be used for recirculation through the heat exchanger), and to preheat the water. After the desired preheat water temperature and level has been reached, the step is completed.

The exiting of this step is dependent on both the level and temperature being at, or above the preheat level and temperature, at the end of the step. Note: Should the I.T. entered by the operator exceed the preheat temperature, the temperature of the fill water must be increased until the preheat temperature achieved is greater than the I.T. entered by the operator.

Note: RPM during Come-Up / Fill – for rotational cooks, the rotation may begin in this step, depending on the configuration of the recipe. It should be noted that rotating at high speeds without the buoyancy of the filled water is detrimental to the rotor and should be controlled with a slow ramp while the machine is being filled.

COME UP – WATER SPRAY

During this step, the pump is turned on, and if a rotary process, the rotation is started (or continues if started in the previous step), and the temperature and pressure are controlled. In order to successfully complete and exit this step, time and temperature conditions established in the recipe (this should be in accordance with the filed process) must be at, or above the recipe requirements. At the end of the scheduled come-up time, the retort must be at, or above, scheduled cook temperature (unless there are multiple come-up steps) to prevent an Uncleared Deviation during the Cook step. If these conditions are not met, the phase time may be extended so that the process exit condition can be reached, without creating a deviation. Flow, level and rpm conditions (if a rotary process) are monitored. If flow, level or rpm’s fall outside of the acceptable range at any time during the step, an Uncleared Deviation Condition is created.

COOK/HOLD/STERILIZATION – WATER SPRAY

The Cook Step involves sterilizing the product after it has reached the established Cook Temperature throughout the retort (the purpose of the Come Up step). In order to successfully complete and exit this phase, the conditions established in the recipe (this should be in accordance with the filed process) must be met for the length of the process. Throughout the scheduled cook time, the retort must be at, or above, scheduled cook temperature, at or above a safe water level to prevent cavitations of the pump – an empirically-predetermined level, and at acceptable RPM speeds (if rotary process). If the temperature condition is not met, and an alternate process is available to the controller, a Deviation condition is created and the cook time may be extended by the alternate. If no alternate is available, then an Uncleared Deviation condition is created.

Flow, level and rpm conditions (if a rotary process) continue and are monitored. If GPM flow or rpm’s fall outside of the acceptable range at any time during the step, an Uncleared Deviation Condition is created. If an Uncleared Deviation condition exists at the end of the scheduled time, the process step can be exited only by an operator override.

During this step, the operator is required to make operator entries: at least one check and entry of the MIG reading, one for the Chart reading, and one for the Sight Glass Level check. All operator entries must be made for the step to be completed. Should the sight glass Level check indicate a failure (water is visibly below the spray level), then an Uncleared Deviation condition would be created.

PRESSURE COOL – WATER SPRAY

This step initiates the indirect cooling process in the Process Vessel. The process water used to sterilize the product is run through a heat exchanger and back into the vessel. External cooling water is run on the outside of the heat exchanger to cool the water inside of the vessel.

When the pressure cool time is completed and an established temperature setpoint in the Process Vessel is achieved, the step ends. Note: Circulation (Flow) and Rpm control (if a rotary process) continue.

ATMOSPHERIC COOL – WATER SPRAY

This step continues the cooling process in the Process Vessel. Cooling water continues to flow into the heat exchanger, while pressure has been reduced to virtually no overpressure (The Vent valve is typically opened, which releases pressure – note: this pressure may be steadily released using ramp control in a Pressure Cool step). When the atmospheric cool time is completed, and an established temperature setpoint in the Process Vessel is achieved, the step ends. Note: Circulation (Flow) and Rpm’s (if a rotary process) continue.

DRAIN – WATER SPRAY

This step drains the water from the retort. The drain is opened the water gravity-drains from the retort. When the level condition is met, the step ends. Note: To accelerate the drain step, limited overriding air pressure (2-5 psi) may be used during the step.

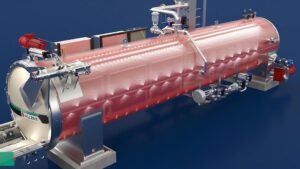

Click above image to view an animation of the water spray proces with Gentle Motion agitation

A complete line of retort room equipment, including water spray (rotary) retorts. See Allpax Spray Retorts.