Shelf stable food packaging has significantly evolved during the past 20 years, from the standard metal can and glass jar, to value-added polymeric and composite pouches, bowls, cups, and trays. Because of this progression, the ordinary saturated steam or static water immersion retort has been found to be inadequate for delivering an optimum thermal process to these new containers. Retort technology has kept pace with the container evolution, advancing to more complex overpressure sterilizers that use a variety of heating and cooling mediums coupled with overpressure to deliver the required thermal process while ensuring package integrity is not compromised.

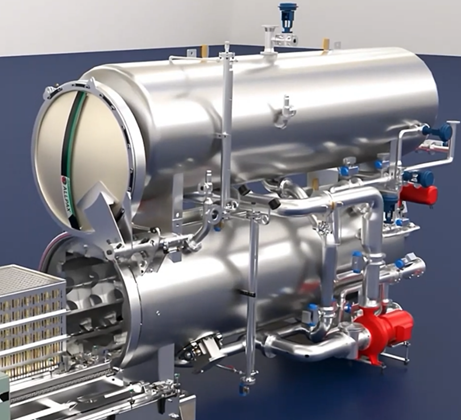

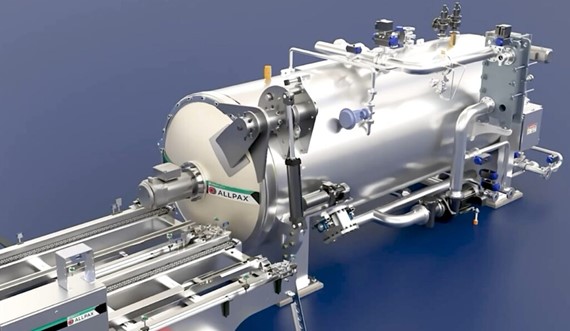

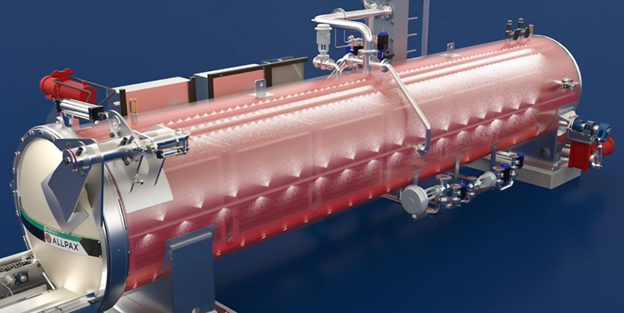

Not all batch retorts are created equal when it comes to processing flexible packages. Standard production retort offerings from many present retort manufacturers include Static and Rotary Steam/Water Spray, Static Water Cascade, Rotary Water Immersion, and Static and Rotary Steam/Air models, all capable of overpressure processing. Also available to the food industry are some horizontal continuous sterilizers capable of delivering saturated steam or overpressure processes with axial rotation, and vertical hydrostatic sterilizers capable of delivering static saturated steam or overpressure processes. Because of the container inflexibility and limited ability to optimize the thermal processes, continuous retorts are best suited for commodity style products packed in metal cans (i.e.: vegetables in brine, pet foods, etc.). This paper will forego the pros and cons of the continuous models due to the considerably large capital expenditures associated with these units and the belief that batch retorts offer the greatest flexibility when it comes to food preservation. In addition to the old standby, saturated steam retorts, Allpax offers all other types of batch retorts. Most are available as static or agitating models.

Some retorts are capable of delivering multiple process modes, not locking the food manufacturer into a large capital investment that may have limited capability with different package designs. Maybe one day you are processing metal cans that do not require overpressure, and the next day pouches which does require overpressure. The multimode retort designs provide the flexibility to adapt to changes in types of containers that are to be run. Saturated steam mode for handling metal double-seamed cans, and steam/water spray with overpressure mode for handling flexible packages.

Overpressure Retort Designs

The one common connection amongst all modern overpressure retorts is the need to mechanically move or “stir” the heating and cooling media. Generally this is accomplished with a pump for Water Immersion, Steam/Water Spray and Water Cascade retorts, or with a high velocity fan in the case of Steam/Air retorts. The premise is to maintain a sufficiently high enough flow rate throughout the retort to ensure temperature equilibrium. The objective is to make sure every container sees the same temperature profile while providing a counterbalance to the pressure created inside the package.

Probably the most important attribute of any retort is its ability to provide a uniform thermal treatment to all containers. This is best accomplished by directing the heating and cooling media parallel to the main heat transfer surfaces of the container. For example, the main heat transfer surface of most cylindrical containers when the can height exceeds the diameter is the sidewall of the container – compared to the container’s ends. For pouches and low profile bowls and trays, the tops and bottoms of these containers will transfer most of the heat energy to the container. In both cases, the optimum flow of the heating and cooling media will be parallel to these surfaces.

So which retort is best suited for which package? Is there a “one retort that fits all”?

The answers to these questions could certainly draw the ire of most retort manufacturers that limit their product line to a single retort type. This is not the intent of this paper. If political correctness, or in this case, “retort correctness” were the objective, then the imparting of relevant information would not be accomplished. With that said, we offer our opinions based on decades of hands-on experience in retort design and testing of every type of retort that is commercially available today, and with every type and size of container imaginable.

Water Immersion Processing

The static version of this retort type has been in use for decades, well before the rotary variant models were invented. The static versions come in both vertical and horizontal models. The vertical models typically use compressed air injected at the bottom of the vessel to promote circulation, and to create overpressure. The horizontal models typically use a pump to circulate the process water from bottom to top, with either air or steam injected above the water level to create overpressure.

The operational principle of the vertical model is quite simple. For the horizontal models, it is more complex. For vertical retorts, the vessel is filled with process water, and some degree of preheating this water takes place before the baskets of product are lowered into the sterilizer. The water level should be above the top-most containers. After loading the retort, the vessel lid is closed and steam mixed with air is introduced at the bottom of the retort. As previously stated, the compressed air injected at the bottom of the shell has a two-fold purpose…….to promote circulation and to create overpressure. These retorts are ideally suited for cylindrical containers standing upright in the baskets because the water flow is parallel to the main transfer surfaces of the container. Containers having these surfaces perpendicular to the flow of water (i.e. pouches, trays, and flat metal cans) will provide more resistance to flow, and by doing this, hot and cold spots inside the retort load will typically develop.

For horizontal models, the product baskets are rolled into the empty retort vessel, the vessel door is closed, and typically preheated process water is transferred from a separate storage vessel. Once the proper water level is attained (above the top-most containers), a circulation pump is turned on thus drawing the process water from the bottom of the vessel and sending it through a mixing chamber where steam is directly injected, or through a heat exchanger where indirect heating of the process water occurs. The heated process water is then returned to the top of the retort vessel, or through a number of inlet ports enveloping the retort baskets.

Overpressure in the most common horizontal models can be more complex than in the vertical units. The most common method of creating overpressure is through the use of a secondary storage vessel piggybacked onto the process vessel. This second vessel serves two purposes. First, it is used to preheat the process water to very high temperatures, reducing the length of the Come-Up Time. Once the retort door is closed, this superheated hot water is transferred to the lower process vessel. The storage vessel is sized so that its water holding capacity is slightly greater than that of the process vessel when the process vessel is filled with containers. Once the transfer of preheated water is complete, there must be a residual amount of this water remaining in the storage vessel to ensure proper pressure control. Via a connection valve, the storage and process vessels remain “connected” during the heating steps, and the initial cooling step. Steam pressure above the residual water in the storage vessel is maintained at the desired overpressure in the process vessel, and this overpressure translates down from the storage to the process vessel via the connection valve.

In simpler types of horizontal water immersion retorts, the process vessel is isolated from the preheat storage vessel once the water transfer is complete. Overpressure in the process vessel is accomplished by the introduction of compressed air into the headspace above the water level. Once the proper water level is attained, a circulation pump is turned on thus drawing the process water from the bottom of the vessel, sending it through a mixing chamber where steam is directly injected, or through a heat exchanger where indirect heating of the process water occurs. The heated process water is then returned to the top of the process vessel, or through a number of inlet ports enveloping the retort baskets.

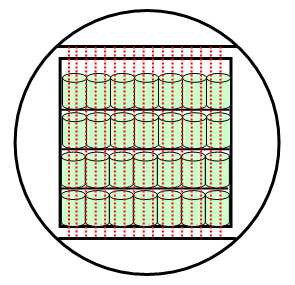

Most of the horizontal water immersion retorts will have 1 – 3 rows of ports where the water re-enters at the top of the vessel. Depending upon how well these ports envelop the retort baskets will determine the optimal container geometry for processing in these retorts. Those that introduce the water above the baskets are best suited for cylindrical containers, for the same reason mentioned in the vertical retort section. For horizontal retorts that have a multitude of entry ports along the top and the sides, the package geometry becomes less of an issue provided the entry force of the water is sufficient to penetrate the load.

Rotation of the retort load facilitates even temperature distribution inside these retorts by thoroughly mixing the process water. The most common rotary horizontal retorts are of the water immersion type. Water provides buoyancy to the load, creating less stress on the rotating mechanism and on the containers (i.e.: glass jars and bottles in particular). Rotating the retort load has many positive benefits, one of which is to provide better heat transfer because the system is not totally dependent on a circulation pump to adequately achieve even temperature distribution inside the process vessel.

Water Cascade Processing

This retort type is often referred to as cascade, trickle, shower, or raining retorts because the process water showers over the retort load.

The operational principle is simple. Process water is drawn from the bottom of the retort via a pump, circulated through an external heat exchanger where the water is indirectly heated, and then redistributed at the top of the retort. The process water flows across a perforated water distribution plate spanning the top of the retort, and cascades into the product baskets. The distribution plate is typically the same width as the retort baskets, and the same length (front to rear inside the retort) as the combined length of all the baskets representing a full load. The number and size of the holes in the top distribution plate is critical for ensuring the process water flows evenly across the entire load. And in most systems, the 4 vertical sides of the retort baskets are solid, which helps channel the process water through the basket. Water level is maintained below the bottom of the retort baskets, and the perforated basket bottoms should be designed so that they do not restrict the flow of the water through the load. The following is a simple depiction of this retort.

Using the premise that heat transfer is optimized when the heating and cooling media flow is parallel to the main transfer surfaces of the container, then these retorts are ideally suited for cylindrical containers (cans and glass jars) standing upright in the retort basket. Containers that have these surfaces perpendicular to the flow of the cascading water (i.e.: pouches, trays, and flat metal cans) will generate more resistance to flow, and by doing this, hot and cold spots inside the retort load can develop.

Also with these retorts, due to the dynamics of flow and the fact that the process water is heated externally, the containers at the top of the baskets heat faster than those at the bottom. As the heated water flows into the basket, the first containers to contact this water absorb much of the heat energy. As the water flows down through the basket, there is less available heat energy for the containers at the basket bottom, particularly during the come-up and early part of the cook hold step. During cooling, the containers at the top cool faster than those at the bottom, so there is some “balancing” of the heat received by all containers. However, for those processors that rely on heating-only lethality when determining the length of the thermal process necessary for Commercial Sterility, then those containers at the top of the basket will most certainly receive more of a heat treatment before the bottom containers reach the target lethality.

Steam/Air Processing

For various technical and therefore “FDA acceptance” reasons, this is not a common retort type used in the US, although they are quite common in Europe and other parts of the world..

As with the water cascade retort, the operational principle is relatively simple. Steam is injected at the bottom of the vessel and vented out of the top to remove most of the residual air. Overpressure control is maintained by adding compressed air into the shell and venting excess pressure out of the shell. Condensate created due to the transfer of heat is expelled from the bottom of the retort’s shell.

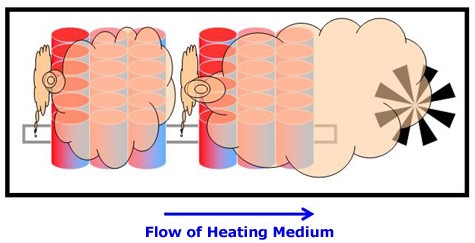

The distinguishing feature of the steam/air retorts is the use of a high-speed fan to circulate the steam/air mixture. This is an extremely important function for maintaining a homogeneous mix of the steam and air because if circulation fails, then pockets of air could insulate containers in the load. This could result in an under-processing condition.

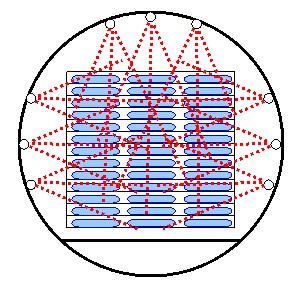

The most common steam/air models have a single high-speed fan mounted at one end of the retort. In these retorts, the steam/air mixture is pulled toward the fan and is then forced back to the opposite end of the retort shell behind solid baffles that shroud the lateral sides of the retort baskets. Once the mix reaches the end of the shell opposite the fan, the domed endcap forces the steam/air back through the retort baskets toward the fan. In these retorts, the flow of the steam/air heating medium is horizontal or parallel to the top and bottom of the retort shell. The following depicts the basic concept of the steam/air retort:

In most of the “horizontal flow” steam/air models, the 4 vertical sides of the retort baskets are open to allow unrestricted flow of the heating medium. Because the flow is horizontal, these retorts are ideally suited for “flat” containers. Pouches and low-profile trays and cans are the most ideal types of containers suited for this retort type.

Some steam/air retorts use multiple fans, one mounted above each basket, to circulate the heating medium. Steam is injected below the retort baskets, and the flow direction is vertical (bottom to top, toward the fan). As with the water cascade retorts, these retorts are ideally suited for cylindrical containers (cans and glass jars) standing upright in the retort basket. Containers that have the main heat transfer surfaces perpendicular to the flow of the process medium (i.e.: pouches, trays, and flat metal cans) will provide more resistance to flow, and by doing this, hot and cold spots inside the retort load can develop.

With any of the steam/air retorts, horizontal or vertical flow, the side of the basket closest to the emission point of steam from the steam spreader(s) will generally heat faster because the containers along this side are exposed first to the heat. As the steam/air mix flows through the basket, there is less available heat energy for the containers at the opposite side from where the steam enters the basket. As with the water cascade models, temperature eventually equilibrates sometime during the early part of the cook hold step.

Steam/Water Spray Processing

As with the water cascade retorts, the operational principle is pretty simple. Process water is filled into the bottom of the retort, to a level in the void (i.e.: bilge area) below the baskets. If a preheat steam spreader is installed in this area, the water may be preheated to a recipe temperature prior to closing the door and starting the process. If there is no steam spreader in the bilge area, then the process will start with the ambient water temperature water that is in, or that is fed into the bilge area.

The process water is drawn from the bottom of the retort via a pump and is either directly heated by steam via full vessel length steam spreader(s) located below the product load in the vessel, or indirectly via a heat exchanger. The process water is then distributed through a series of distribution pipes positioned around the retort baskets, which are fitted with many fan-type spray nozzles. Allpax offers both styles, indirect and direct heating of the process medium.

When heating is by direct steam injection into the retort shell, the turbulence created by the water exiting the spray nozzles mixes the steam and air environment to create a homogeneous heating medium.

Just as the steam/air retorts use some of the air contained within the retort when the door is closed and heating begins to create an overpressure environment, so does the water spray retort. Overpressure control is maintained by either venting excess pressure out of the shell or adding compressed air into the shell.

The key to the water spray retort is its ability to take the process water and spray it turbulently throughout the retort. The water re-enters the process shell through specially designed nozzles that “atomize” it into very small droplets. The spray pattern from the nozzles is usually conical, and this creates overlapping spray patterns throughout the retort. In properly designed water spray retorts, there are virtually no dead spots as demonstrated below.

The early models typically had 1-3 distribution pipes suspended above the retort baskets, with spray nozzles spaced ~6-12 inches apart, directing the spray across the top of the retort load.

The Allpax Water Spray retorts allow for a customized number and location of the distribution pipes and spray nozzles depending on the type and orientation of the container, usually encircling the load on three sides for maximum process medium penetration, thus resulting in optimal temperature distribution.

Cooling is typically done through an external plate and frame heat exchanger, and again, usually cooling medium penetration is from 3 sides of the retort basket, minimizing hot spots that can occur with single direction cooling medium flows.

Static vs. Rotary vs. Horizontal Reciprocation Agitation

The thermal process and finished product quality can be greatly enhanced for some containers and products by moving the container load during the proces cycle. Movement or agitation of the container load forces convection heating of the product inside the container. The level of convection is predicated by the headspace or void inside the container, the viscosity of the product, the container’s geometry, the orientation of the container, and the type of movement applied to the container load.

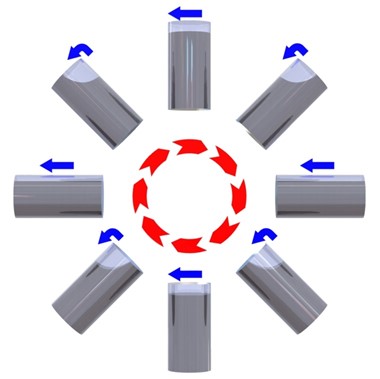

One of the more common types of forced convection batch retort processing uses end-over-end (EOE) rotation of the containers. Historically metal cans, glass jars and polymeric bowls benefit from EOE rotation because of the ease in controlling the headspace, and the rigidity of the container helps to maintain this void. However, some pouched products subjected to lower rotation speeds (<10 RPM’s) show that the products in these containers can also benefit from EOE rotation, provided the headspace (typically measured as level of residual gas) is controlled well.

In the EOE process mode, the rigid cylindrical containers are usually placed upright inside the retort baskets, and the containers are rotated as shown below.

The rotor inside the retort rotates the baskets end over end at speeds ranging from 2-25 RPM. This forces the headspace bubble inside the container to move from the container wall through the center of the container, forcing hot and cooler regions to thoroughly mix. The mixing greatly reduces the length of time required to produce a sterile product. Process reductions of as much as 60% below static processing methods are possible.

EOE is generally better suited for water immersion processes because the water provides buoyancy to the retort load, and this relieves some of the stress placed on the containers, and on the drive mechanism and the trunnion rollers supporting the insert and product load inside of it.

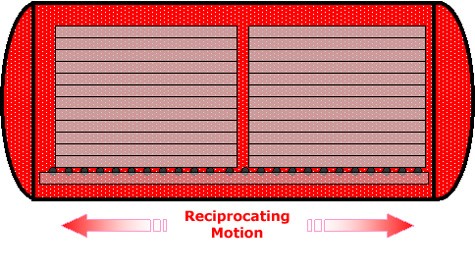

Horizontal reciprocating agitation is another method of forcing product convection inside the container. This is a relatively new technology in which horizontally oriented containers, like pouches or trays, are placed on trays that are stacked to form a cube. Once loaded into the retort, the cubes are subjected to a reciprocating forward and backward motion to impart agitation of the product inside the containers. Allpax Gentle-Motion type retorts are capable of providing reciprocating speeds from 0 to 60 forward and backward strokes per minute. Allpax SHAKA type retorts are capable of providing reciprocating rates up to 360 six-inch strokes per minute!!

Gentle Motion or SHAKA processing can take place in a Saturated Steam or Water Spray processing environment. These modes maximize the penetration of the heating medium through the retort load. Recall that Saturated Steam processing is best suited for metal containers employing a double-seam closure, whereas Water Spray with overpressure processing can be used for all container types.

Retort pouches and low-profile trays, horizontally oriented, are best suited for Gentle Motion and SHAKA agitation methods due to the low-profile container geometry. The back and forth agitation motion helps to force effective convective heating and cooling inside the containers. For vertically oriented containers, like rigid cans or glass jars/bottles, reciprocating type agitation does not create enough turbulence inside the container to produce process time savings and/or product quality benefits.

Summary

A retort is generally one of the most expensive pieces of equipment in a processing plant and, usually the longest lasting. We commonly see retorts that have been in use for well over 40 years. In today’s fast-changing market-driven industry where appearance and convenience are everything, production plants often have no idea what products and containers are around the next corner. For these reasons, many companies choose batch retorts for their inherent flexibility attributes (compared to continuous sterilization or aseptic systems) and are more often electing to go with multi-mode retort systems to maximize the flexibility of their batch retorting operation.